An uninterruptible power supply, or UPS, is like any other piece of electrical equipment: it needs to receive proper maintenance to deliver the reliable service it was designed to provide. UPS manufacturers provide basic guidelines for delivering this maintenance, although units that operate in harsh conditions may need additional care and still suffer an increased rate of failure.

Electrical power is an absolute necessity for practically every form of business, and it becomes even more important as electronic equipment becomes a critical part of most businesses. A power failure can be far more than an inconvenience, costing a business tremendous amounts of time and money. UPSs are intended to protect vital electronic and mechanical equipment, such as the SWL2500EFR battery. That protection can be amplified and strengthened by establishing a UPS maintenance programme.

Here are five key reasons a business must maintain its UPSs properly.

1) Downtime Prevention

When machines that are critical to a business’s operations suffer a power loss, the ensuing downtime can cost the organisation thousands of pounds. The risk is the same whether the machines in question are computer servers or industrial tools. If the business has a UPS system in place, this downtime can be avoided – so long as the UPSs switch over successfully and do not fail before the restoration of mains power. UPS maintenance ensures that these disastrous outcomes are less likely.

2) Data Loss Prevention

Computer equipment in a growing number of businesses holds extremely sensitive data. Digital information may be vital to the business itself, to its customers, or to key partners. It does not take a complete power outage to destroy important data; sometimes a mere lag in the power supply can cause data loss. UPSs need to be properly maintained so that they come into play instantaneously when mains power is lost.

3) Optimum UPS Efficiency

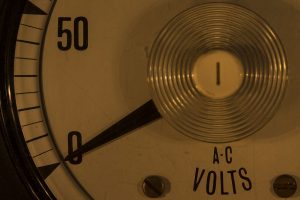

A UPS relies on capacitors to fulfil its job. If the unit is to function efficiently throughout its lifetime, these capacitors need to be kept as close as possible to the environmental conditions for which they were designed. To safeguard life-long efficiency, a UPS needs to be kept in a clean, dry, climate-controlled space. Any performance data the UPS produces (such as alarms, indicators, and logs) should be properly recorded so that appropriate action can be taken.

In a comprehensive UPS maintenance programme, every critical part of the UPS installation would receive regular maintenance. Every maintenance visit should include an inspection of the UPS’s parts and diagnostic readouts. A maintenance visit should also confirm that all of the installation’s communications tools – from remote monitoring telemetry to onboard indicator lamps – are functioning properly.

4) Battery Health Maximisation

Many UPS systems rely on valve-regulated lead-acid (VRLA) batteries. These batteries spend most of their time in ‘float mode,’ trickle charging from mains power to maintain maximum charge. When the UPS is put into action and starts supplying power, the batteries discharge. Battery life expectancy depends on how often and how fully they are discharged. VRLA batteries are expressly designed for standby service, and they will wear out faster the more frequently they are cycled.

UPS batteries should be inspected on an annual or semi-annual basis so that the end of each battery’s useful life can be accurately predicted. Battery health can be ascertained by performing impedance and load tests on each UPS.

5) Provision for Emergency Repairs

Even with comprehensive maintenance, surprise failures are an inevitable possibility. A comprehensive UPS maintenance programme should include provisions for emergency call-out service to provide swift repairs when necessary. Emergency cover pricing varies widely based on the speed and extent of service provided. Organisations should find an emergency service that will contract to meet their needs in terms of call-out response time, stock holding levels, and any other key performance standards.